Hydraulic Fluid Connectors Market By Product - Global Industry Analysis And Forecast To 2023

Published On : June 2022 Pages : 180 Category: Agrochemicals & Fertilizers Report Code : CM06991

Hydraulic Fluid Connectors Market by Product (Mobile Hydraulic and Stationary Hydraulic) Forecast to 2017 to 2023

Industry Outlook and Trend Analysis

The Hydraulic Fluid Connectors Market was worth USD 0.46 billion in 2017 and is expected to reach approximately USD 0.86 billion by 2023, while registering itself at a compound annual growth rate (CAGR) of 7.28% during the forecast period. Hydraulic fluid connectors are normally metal connectors used to join any water driven liquid conveyor, for example, hose, pipe, or tube to other pressure driven devises which may incorporate water driven pumps, water powered engine, supply, chambers, actuators or different hoses and tubes. These connectors are essential for passing on pressure driven liquids starting with one gadget then onto the next. These connectors are widely utilized as a part of aviation domain for essential water powered frameworks, for example, flight controls, stream motor pumps, landing gear component and so forth. These connectors need to meet thorough quality models and tests in order to be utilized as a part of aviation applications.

Drivers & Restrains

Mobile hydraulics and stationary hydraulics are the two fundamental items accessible in the North America advertise for water powered liquid connectors. Portable power through pressure, among the two, have developed as the most esteemed item in this market and is relied upon to keep on being in this situation throughout the following couple of years, on account of the ascent in the interest for new and greater air ship, alongside the ensuing increment in the ground bolster vehicles. The versatile water power section comprises of all the gear, gadgets, and artworks that are mobile, for example, air ship, compartment transporters, baggage dealing with vehicles, and pulls. Airplane terminal material dealing with hardware, for example, compartment loaders, and ground bolster gear, for example, powering vehicles, de-icing machines, portable lifts, loaders, and different other versatile machines are additionally incorporated into portable water power. Then again, the stationary pressure driven item section incorporates stream connect, shed gear, and upkeep hardware as it were.

Regional Outlook and Trend Analysis

The U.S. and Canada are the prime household markets for hydraulic fluid connectors market in North America. With over 85%, the U.S. driven the North America market for hydraulic fluid connectors in 2017. Specialists anticipate that the local market will hold its situation over the imminent years, because of the solid financial development, the nearness of a strong flying industry, and the high extra cash of buyers in this nation. The crunching airfare costs are pulling in an expansive number of travellers to movement through air for residential excursions, which is likewise anticipated that would impel the common flying industry, consequently invigorating the U.S. hydraulic fluid connectors market sooner rather than later.

Competitive Insights

The leading players in the market are RYCO Hydraulics Pty. Ltd., Parker Hannifin Corp., Eaton Corp. Plc. and Others. The major players in the market are profiled in detail in view of qualities, for example, company portfolio, business strategies, financial overview, recent developments, and share of the overall industry.

The Hydraulic Fluid Connectors Market region-wise is segmented as follows-

By Region

- North America

- U.S.

- Canada

- Mexico

- Europe

- Germany

- UK

- France

- Russia

- Italy

- Rest of Europe

- Asia-Pacific

- China

- Japan

- South Korea

- India

- Southeast Asia

- Rest of Asia-Pacific

- South America

- Brazil

- Argentina

- Columbia

- South Africa

- Rest of South America

- Middle East and Africa

- Saudi Arabia

- UAE

- Egypt

- Nigeria

- South Africa

- Rest of MEA

Some of the key questions answered by the report are:

- What was the market size in 2017 and forecast from 2017 to 2023?

- What will be the industry market growth from 2017 to 2023?

- What are the major drivers, restraints, opportunities, challenges, and industry trends and their impact on the market forecast?

- What are the major segments leading the market growth and why?

Which are the leading players in the market and what are the major strategies adopted by them to sustain the market competition?

Market Classification

· Hydraulic Fluid Connectors Market, By Product, Estimates and Forecast, 2014-2023($Million)

· Mobile Hydraulic

· Stationary Hydraulic

· Hydraulic Fluid Connectors Market, By Region, Estimates and Forecast, 2014-2023($Million)

o North America

§ North America Hydraulic Fluid Connectors Market, By Country

o U.S. Hydraulic Fluid Connectors Market

o Canada Hydraulic Fluid Connectors Market

o Mexico Hydraulic Fluid Connectors Market

o Europe

§ Europe Hydraulic Fluid Connectors Market, By Country

o Germany Hydraulic Fluid Connectors Market

o UK Hydraulic Fluid Connectors Market

o France Hydraulic Fluid Connectors Market

o Russia Hydraulic Fluid Connectors Market

o Italy Hydraulic Fluid Connectors Market

o Rest of Europe Hydraulic Fluid Connectors Market

o Asia-Pacific

§ Asia-Pacific Hydraulic Fluid Connectors Market, By Country

o China Hydraulic Fluid Connectors Market

o Japan Hydraulic Fluid Connectors Market

o South Korea Hydraulic Fluid Connectors Market

o India Hydraulic Fluid Connectors Market

o Southeast Asia Hydraulic Fluid Connectors Market

o Rest of Asia-Pacific Hydraulic Fluid Connectors Market

o South America

§ South America Hydraulic Fluid Connectors Market

o Brazil Hydraulic Fluid Connectors Market

o Argentina Hydraulic Fluid Connectors Market

o Columbia Hydraulic Fluid Connectors Market

o South Africa Hydraulic Fluid Connectors Market

o Rest of South America Hydraulic Fluid Connectors Market

o Middle East and Africa

§ Middle East and Africa Hydraulic Fluid Connectors Market

o Saudi Arabia Hydraulic Fluid Connectors Market

o UAE Hydraulic Fluid Connectors Market

o Egypt Hydraulic Fluid Connectors Market

o Nigeria Hydraulic Fluid Connectors Market

o South Africa Hydraulic Fluid Connectors Market

o Rest of MEA Hydraulic Fluid Connectors Market

Table of Contents

Chapter1. Introduction

1.1. Report Description

1.2. Research Methodology

1.2.1. Secondary Research

1.2.2. Primary Research

Chapter 2. Executive Summary

2.1. Key Highlights

Chapter 3. Market Overview

3.1. Introduction

3.1.1. Market Definition

3.1.2. Market Segmentation

3.2. Market Dynamics

3.2.1. Drivers

3.2.2. Restraints

3.2.3. Opportunities

3.2.3.1. Emerging Countries to Offer Lucrative Growth Opportunities

Chapter 4. Market Analysis by Regions

4.1. North America (United States, Canada and Mexico)

4.1.1. United States Market States and Outlook (2017-2023)

4.1.2. Canada Market States and Outlook (2017-2023)

4.1.3. Mexico Market States and Outlook (2017-2023)

4.2. Europe (Germany, France, UK, Russia, Italy and Rest of Europe)

4.2.1. Germany Market States and Outlook (2017-2023)

4.2.2. France Market States and Outlook (2017-2023)

4.2.3. UK Market States and Outlook (2017-2023)

4.2.4. Russia Market States and Outlook (2017-2023)

4.2.5. Italy Market States and Outlook (2017-2023)

4.2.6. Rest of Europe Market States and Outlook (2017-2023)

4.3. Asia-Pacific (China, Japan, Korea, India, Southeast Asia and Rest of Asia-Pacific)

4.3.1. China Market States and Outlook (2017-2023)

4.3.2. Japan Market States and Outlook (2017-2023)

4.3.3. Korea Market States and Outlook (2017-2023)

4.3.4. India Market States and Outlook (2017-2023)

4.3.5. Rest of Asia-Pacific Market States and Outlook (2017-2023)

4.4. South America (Brazil, Argentina, Columbia and Rest of South America)

4.4.1. Brazil Market States and Outlook (2017-2023)

4.4.2. Argentina Market States and Outlook (2017-2023)

4.4.3. Columbia Market States and Outlook (2017-2023)

4.4.4. Rest of South America Market States and Outlook (2017-2023)

4.5. Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, South Africa and Rest of MEA)

4.5.1. Saudi Arabia Market States and Outlook (2017-2023)

4.5.2. UAE Market States and Outlook (2017-2023)

4.5.3. Egypt Market States and Outlook (2017-2023)

4.5.4. Nigeria Market States and Outlook (2017-2023)

4.5.5. South Africa Market States and Outlook (2017-2023)

4.5.6. Rest of MEA Market States and Outlook (2017-2023)

Chapter 5. Hydraulic Fluid Connectors Market, By Product

5.1. Introduction

5.2. Global Hydraulic Fluid Connectors Sales, Revenue and Market Share by Product (2017-2027)

5.2.1. Global Hydraulic Fluid Connectors Sales and Sales Share by Product (2017-2027)

5.2.2. Global Hydraulic Fluid Connectors Revenue and Revenue Share by Product (2017-2027)

5.3. Mobile Hydraulic

5.3.1. Global Mobile Hydraulic Sales and Growth Rate (2017-2027)

5.4. Stationary Hydraulic

5.4.1. Global Stationary Hydraulic Sales and Growth Rate (2017-2027)

Chapter 6. Hydraulic Fluid Connectors Market, By Region

6.1. Introduction

6.2. Global Hydraulic Fluid Connectors Sales, Revenue and Market Share by Regions

6.2.1. Global Hydraulic Fluid Connectors Sales by Regions (2017-2027)

6.2.2. Global Hydraulic Fluid Connectors Revenue by Regions (2017-2027)

6.3. North America Hydraulic Fluid Connectors by Countries

6.3.1. North America Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.3.2. North America Hydraulic Fluid Connectors Revenue and Growth Rate (2017-2027)

6.3.3. North America Hydraulic Fluid Connectors Sales by Countries (2017-2027)

6.3.4. North America Hydraulic Fluid Connectors Revenue (Million USD) by Countries (2017-2027)

6.3.5. U.S.

6.3.5.1. United States Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.3.5.2. United States Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.3.6. Canada

6.3.6.1. Canada Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.3.6.2. Canada Hydraulic Fluid Connectors Sales (Millions USD) and Growth Rate (2017-2027)

6.3.7. Mexico

6.3.7.1. Mexico Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.3.7.2. Mexico Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.4. Europe Hydraulic Fluid Connectors by Countries

6.4.1. Europe Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.4.2. Europe Hydraulic Fluid Connectors Revenue and Growth Rate (2017-2027)

6.4.3. Europe Hydraulic Fluid Connectors Sales by Countries (2017-2027)

6.4.4. Europe Hydraulic Fluid Connectors Revenue (Million USD) by Countries (2017-2027)

6.4.5. Germany

6.4.5.1. Germany Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.4.5.2. Germany Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.4.6. UK

6.4.6.1. UK Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.4.6.2. UK Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.4.7. France

6.4.7.1. France Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.4.7.2. France Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.4.8. Russia

6.4.8.1. Russia Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.4.8.2. Russia Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.4.9. Italy

6.4.9.1. Italy Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.4.9.2. Italy Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.4.10. Rest of Europe

6.4.10.1. Rest of Europe Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.4.10.2. Rest of Europe Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.5. Asia-Pacific

6.5.1. Asia-Pacific Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.5.2. Asia-Pacific Hydraulic Fluid Connectors Revenue and Growth Rate (2017-2027)

6.5.3. Asia-Pacific Hydraulic Fluid Connectors Sales by Countries (2017-2027)

6.5.4. Asia-Pacific Hydraulic Fluid Connectors Revenue (Million USD) by Countries (2017-2027)

6.5.5. China

6.5.5.1. China Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.5.5.2. China Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.5.6. Japan

6.5.6.1. Japan Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.5.6.2. Japan Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.5.6.3.

6.5.7. Korea

6.5.7.1. Korea Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.5.7.2. Korea Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.5.8. India

6.5.8.1. India Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.5.8.2. India Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.5.9. Southeast Asia

6.5.9.1. Southeast Asia Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.5.9.2. Southeast Asia Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.5.10. Rest of Asia-Pacific

6.5.10.1. Rest of Asia-Pacific Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.5.10.2. Rest of Asia-Pacific Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.6. South America

6.6.1. South America Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.6.2. South America Hydraulic Fluid Connectors Revenue and Growth Rate (2017-2027)

6.6.3. South America Hydraulic Fluid Connectors Sales by Countries (2017-2027)

6.6.4. South America Hydraulic Fluid Connectors Revenue (Million USD) by Countries (2017-2027)

6.6.5. Brazil

6.6.5.1. Brazil Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.6.5.2. Brazil Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.6.6. Argentina

6.6.6.1. Argentina Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.6.6.2. Argentina Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.6.7. Columbia

6.6.7.1. Columbia Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.6.7.2. Columbia Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.6.8. Rest of South America

6.6.8.1. Rest of South America Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.6.8.2. Rest of South America Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.7. Middle East and Africa

6.7.1. Middle East and Africa Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.7.2. Middle East and Africa Hydraulic Fluid Connectors Revenue and Growth Rate (2017-2027)

6.7.3. Middle East and Africa Hydraulic Fluid Connectors Sales by Countries (2017-2027)

6.7.4. Middle East and Africa Hydraulic Fluid Connectors Revenue (Million USD) by Countries (2017-2027)

6.7.5. Saudi Arabia

6.7.5.1. Saudi Arabia Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.7.5.2. Saudi Arabia Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.7.6. United Arab Emirates

6.7.6.1. United Arab Emirates Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.7.6.2. United Arab Emirates Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.7.7. Egypt

6.7.7.1. Egypt Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.7.7.2. Egypt Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.7.8. Nigeria

6.7.8.1. Nigeria Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.7.8.2. Nigeria Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.7.9. South Africa

6.7.9.1. South Africa Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.7.9.2. South Africa Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

6.7.10. Rest of Middle East and Africa

6.7.10.1. Rest of Middle East and Africa Hydraulic Fluid Connectors Sales and Growth Rate (2017-2027)

6.7.10.2. Rest of Middle East and Africa Hydraulic Fluid Connectors Revenue (Millions USD) and Growth Rate (2017-2027)

Chapter 7. Company Profiles

7.1. Parker Hannifin Corporation

7.1.1. Business Overview

7.1.2. Product Portfolio

7.1.3. Strategic Developments

7.1.4. Sales, Revenue and Market Share

7.2. Eaton Corporation Plc

7.2.1. Business Overview

7.2.2. Product Portfolio

7.2.3. Strategic Developments

7.2.4. Sales, Revenue and Market Share

7.3. Kurt Hydraulics

7.3.1. Business Overview

7.3.2. Product Portfolio

7.3.3. Strategic Developments

7.3.4. Sales, Revenue and Market Share

7.4. RYCO Hydraulics Pty. Ltd.

7.4.1. Business Overview

7.4.2. Product Portfolio

7.4.3. Strategic Developments

7.4.4. Sales, Revenue and Market Share

7.5. Manuli Hydraulics

7.5.1. Business Overview

7.5.2. Product Portfolio

7.5.3. Strategic Developments

7.5.4. Sales, Revenue and Market Share

7.6. Gates Corporation

7.6.1. Business Overview

7.6.2. Product Portfolio

7.6.3. Strategic Developments

7.6.4. Sales, Revenue and Market Share

7.7. ALFAGOMMA Spa

7.7.1. Business Overview

7.7.2. Product Portfolio

7.7.3. Strategic Developments

7.7.4. Sales, Revenue and Market Share

7.8. B&E Manufacturing Company, Inc.

7.8.1. Business Overview

7.8.2. Product Portfolio

7.8.3. Strategic Developments

7.8.4. Sales, Revenue and Market Share

7.9. Aerocom Specialty Fittings Inc.

7.9.1. Business Overview

7.9.2. Product Portfolio

7.9.3. Strategic Developments

7.9.4. Sales, Revenue and Market Share

7.10. Atlas Specialty Products

7.10.1. Business Overview

7.10.2. Product Portfolio

7.10.3. Strategic Developments

7.10.4. Sales, Revenue and Market Share

Chapter 8. Global Hydraulic Fluid Connectors Market Competition, by Manufacturer

8.1. Global Hydraulic Fluid Connectors Sales and Market Share by Manufacturer (2017-2017)

8.2. Global Hydraulic Fluid Connectors Revenue and Market Share by Manufacturer (2017-2017)

8.3. Global Hydraulic Fluid Connectors Price by Manufacturer (2017-2017)

8.4. Top 5 Hydraulic Fluid Connectors Manufacturer Market Share

8.5. Market Competition Trend

Chapter 9. Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.1. Global Hydraulic Fluid Connectors Sales, Revenue (Millions USD) and Growth Rate (2027-2023)

9.2. Hydraulic Fluid Connectors Market Forecast by Regions (2027-2023)

9.2.1. North America Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.1.1. United States Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.1.2. Canada Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.1.3. Mexico Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.2. Europe Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.2.1. Germany Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.2.2. United Kingdom Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.2.3. France Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.2.4. Russia Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.2.5. Italy Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.2.6. Rest of the Europe Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.3. Asia-Pacific Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.3.1. China Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.3.2. Japan Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.3.3. Korea Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.3.4. India Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.3.5. Southeast Asia Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.3.6. Rest of Asia-Pacific Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.4. South America Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.4.1. Brazil Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.4.2. Argentina Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.4.3. Columbia Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.4.4. Rest of South America Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.5. Middle East and Africa Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.5.1. Saudi Arabia Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.5.2. UAE Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.5.3. Egypt Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.5.4. Nigeria Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.5.5. South Africa Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.2.5.6. Rest of MEA Hydraulic Fluid Connectors Market Forecast (2027-2023)

9.3. Hydraulic Fluid Connectors Market Forecast by Product (2027-2023)

9.3.1. Global Hydraulic Fluid Connectors Sales Forecast by Product (2027-2023)

9.3.2. Global Hydraulic Fluid Connectors Sales Market Share Forecast by Product (2027-2023)

List of Tables

(*You can glance through the list of Tables and Figures when you view the sample copy of Hydraulic Fluid Connectors Market.)

Research Methodology

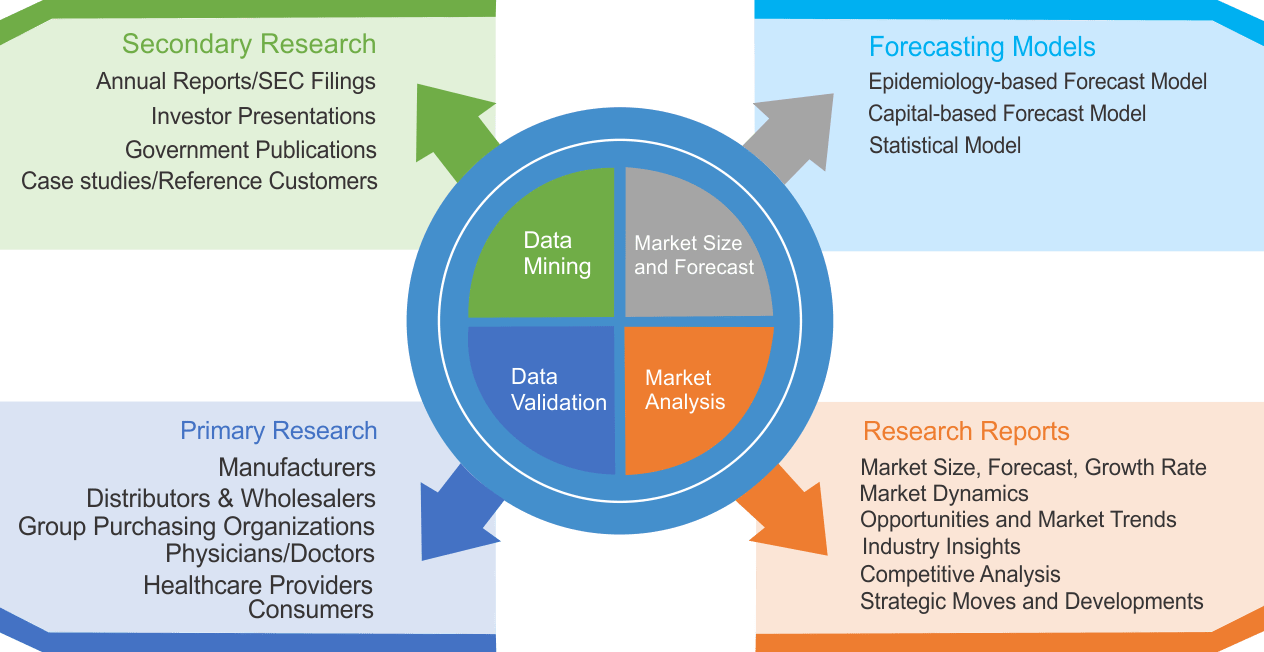

We use both primary as well as secondary research for our market surveys, estimates and for developing forecast. Our research process commence by analyzing the problem which enable us to design the scope for our research study. Our research process is uniquely designed with enough flexibility to adjust according to changing nature of products and markets, while retaining core element to ensure reliability and accuracy in research findings. We understand both macro and micro-economic factors to evaluate and forecast different market segments.

Data Mining

Data is extensively collected through various secondary sources such as annual reports, investor presentations, SEC filings, and other corporate publications. We also refer trade magazines, technical journals, paid databases such as Factiva and Bloomberg, industry trade journals, scientific journals, and social media data to understand market dynamics and industry trends. Further, we also conduct primary research to understand market drivers, restraints, opportunities, challenges, and competitive scenario to build our analysis.

Data Collection Matrix

|

Data Collection Matrix |

Supply Side |

Demand Side |

|

Primary Data Sources |

|

|

|

Secondary Data Sources |

|

|

Market Modeling and Forecasting

We use epidemiology and capital equipment-based models to forecast market size of different segments at country and regional level.

- Epidemiology-based Forecasting Model: This method uses epidemiology data gathered through various publications and from physicians to estimate population of patients, flow of treatment of individual disease and therapies. The data collected through this method includes statics on incidence of disease, population suffering from disease, and treatment population. This method is used to understand:

- Number of patients for particular device or medical procedure and

- Repeated use of particular device depending on health and condition of patient

- Capital-based Forecasting Model: This method of forecasting is based on number of replacements, installed-based and new sales of capital equipment used in various healthcare and diagnostic centers. These three parameters are calculated and forecast is developed. Installation base is calculated as average number of units per facility; while sales for particular year is calculated from number of new and replace units. Secondary data is collected through various supply chain intermediaries and opinion leaders to arrive at installation and sales rate. These techniques help our analysts in validating market and developed market estimates and forecast.

We do forecast on basis of several parameters such as market drivers, market opportunities, industry trends government regulations, raw materials supply and trade dynamics to ensure relevance of forecast with market scenario. With increasing need to granulized information, we used bottom-up methodology for forecasting where we evaluate each regional segment differently and combined all forecast to develop final market forecast.

Data Validation

We believe primary research is a very important tool in analyzing and forecasting different markets. In order to make sure accuracy of our findings, our team conducts primary interviews at every stage of research to gain deep insights into current business environment and future trends and key developments in market. This includes use of various methods such as telephonic interviews, focus groups, face to face interviews and questionnaires to validate our research from all aspects. We validate our data through primary research from key industry leaders such as CEO, product managers, marketing managers, suppliers, distributors, and consumers are frequently interviewed. These interviews provide valuable insights which help us to have better market understanding besides validating our estimates and forecast.

Data Triangulation

Industry Analysis

|

Qualitative Data |

Quantitative Data (2017-2025) |

|

|